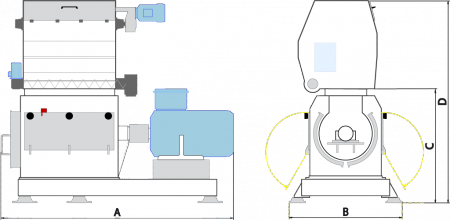

RM and RMP hammermills

FEATURES

- Two-way direction of rotation up to 3600 rpm

- Effective screening area from 0.45 to 2.20 m²

- Quick change of hammers by tilting

- Change of screens during operations

- Continuous control of bearings and grinding chamber temperatures

- Adjustable feeding flap

- Grinding chamber fitted with grooved armor plate and counter-hammers

- Automatic greasing of bearings

RANGE

2 types of our RM hammermills are available:

-

RM type : Manual removal of screens

-

RMP type : Manual removal of screens by means of pneumatic cylinders (French patent n°93-051-88)

This equipment is also available with a grinding chamber with reinforced sealing for fine grinding process.

| Type | Power (kW) |

Hammermill mass with motor and ABMS (kg) |

Quantity of hammers | Effective screening area (m²) |

|---|---|---|---|---|

| RM14 | 45/75 | 3200 | 52 | 0,70 |

| RM18 | 90/132 | 4150 | 92 | 1,25 |

| RM110 | 110/160 | 4550 | 112 | 1,50 |

| RM114 | 180/250 | 5800 | 152 | 2,00 |

| RM116 | 200/355 | 6900 | 168 | 2,20 |

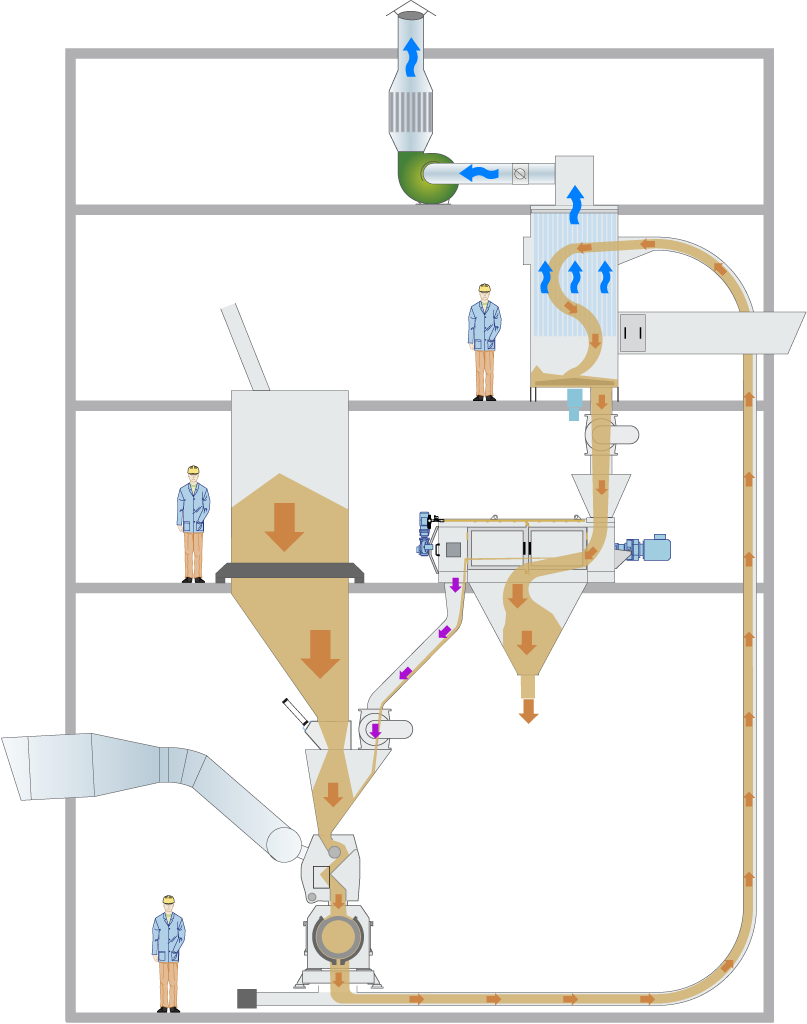

Functional block diagram

Fine grinding

STOLZ has developed a new grinding / sieving concept in order to offer solutions for an even finer grinding dedicated to specific food formulas for extrusion meeting the users requirements.

Our sifters with two-way centrifugal rotation and automatic cleaning while running are mounted at hammermills outlet with 400 to 1600 mm chamber width, and with 37 to 355 kW.

That concept, combined with the RM hammermill reputation and our high quality ABMS pneumatic feeder-metal remover-destoner appeal to several dozens of customers each year.

Documentation

Hammermills type RM, RMP and RMPF

format PDF

Jul 10, 2018

Brochure about hammermills with pneumatic screen unlocking

Grinding lines with pneumatic conveying

format PDF

Jul 10, 2013

Brochure about grinding lines with pneumatic conveying (fine grinding)

Grinding lines with hopper and screw discharge

format PDF

Jul 10, 2013

Brochure about grinding lines with hopper and screw dischage