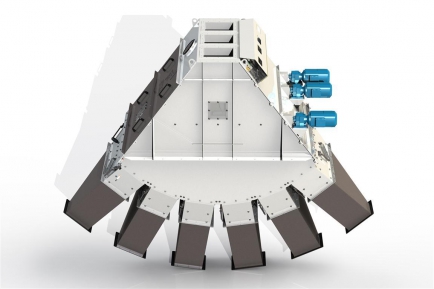

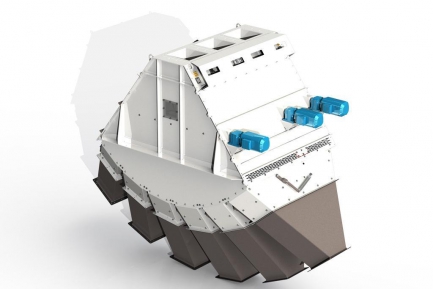

Swing spout distributor

FEATURES

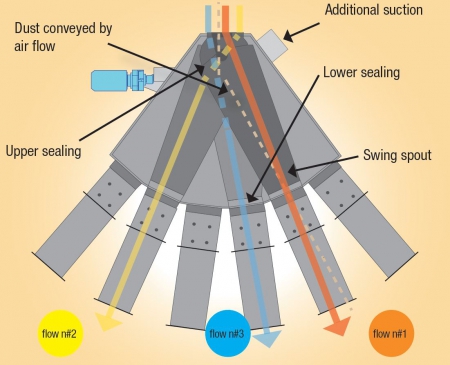

- Independent swing spout controlled by motorized worm screws

- Driving screws fitted with individual cleaning systems

- Swing spout with upper and lower sealings to reduce dust emissions inside the distributor

- Bottom cleaning by air blowing associated to centralized air suction

- Swing spout lined with removable wearing plates

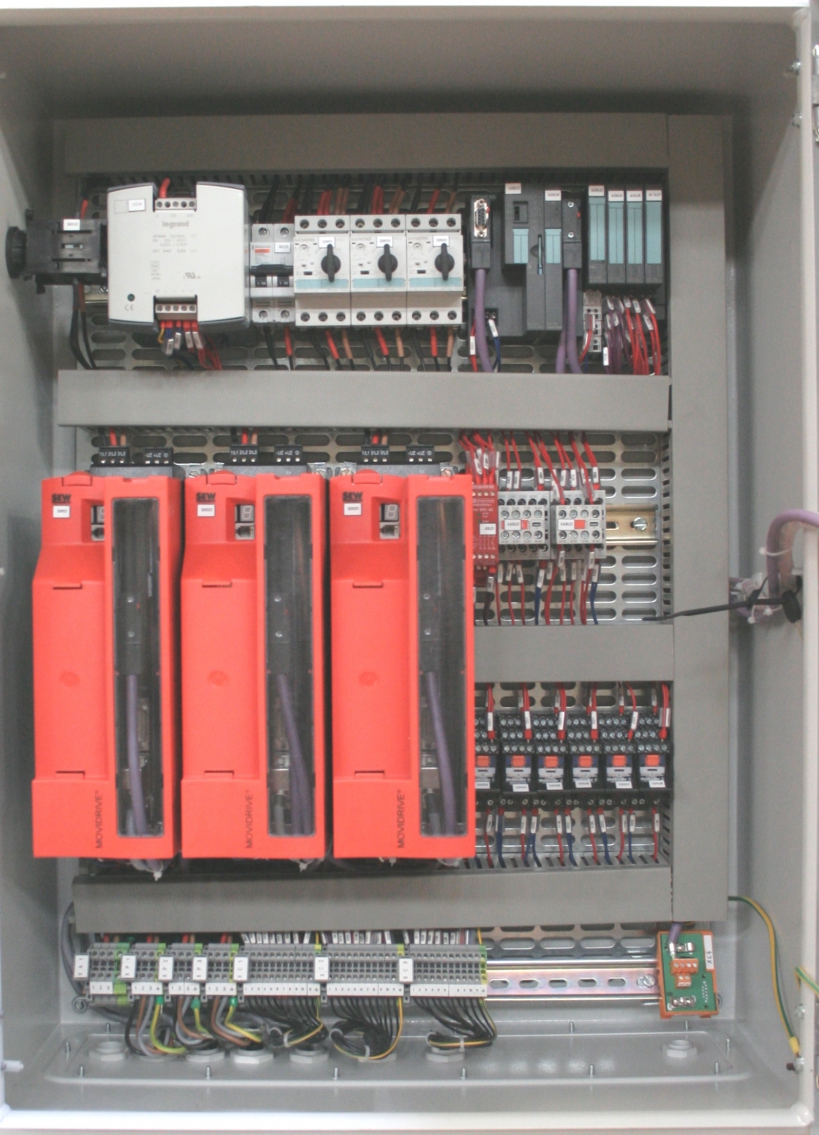

- Built in STOLZ automaton with control cabinet

PURPOSE

The STOLZ swing spout distributor directs several flows of product (powdery or granular) to different circuits at a maximal capacity of 300 tons/hour. Its design limits the danger of explosion or cross contamination.

Regulation

Each equipment complies with 2006/42/EC machine directive and can be supplied compliant with 94/9/EC Atex directive for areas 22 or 21.

Functional block diagram

"Limited risk" version

The ATEX directive and some national regulations constrains industrials to take safety measures in silos to limit the effects of an explosion and to stop its propagation.

The STOLZ swing spout distributor has the advantage to insulate each non used outlet allowing :

- to avoid any risk of cross contamination

- to dramatically lower the danger of explosion transfer between circuits

Every outlet is fitted with an individual seal flap to avoid communication between the different circuits.

The opening of the outlet seal flap is individually controlled by a pneumatic cylinder.

Automation : control cabinet

STOLZ include with the swing spout distributor a control cabinet supporting the following features :

- a management automaton allowing to pilot and stop the swing spout at the required positions

- a remote control by Profibus DP communication (AS-i or wired network supplied as an option)

- a proximity control monitored by the automaton for a local control

Documentation