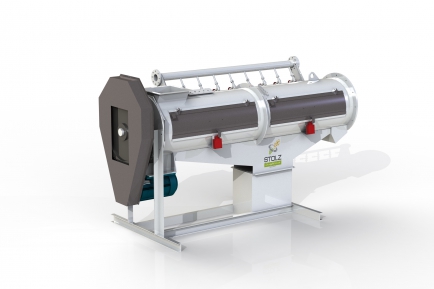

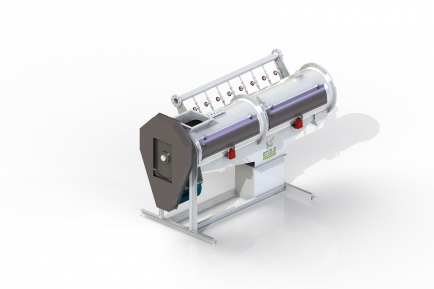

Standard conditioner PEP

FEATURES

-

Rotor with blades with adjustable step

-

Lateral steam inlet

-

Temperature sensors

Options

-

Liquids incorporation rack (molasse, proteinal, sulfite lye)

-

ATEX compliance

PURPOSE

The conditioner is designed for mixing closely steam with meal, thus heating the product up to the suitable temperature for a proper granulation.

Its adjustable blades are designed to set the product progress.

It can eventually receive molasse directly with a small percentage. It is entirely made out of stainless steel.

Depending on the use, the capacity, the specific weight of the product to be compressed, the preparation will be done with one of the STOLZ conditioners. Each conditioner, depending on its design and content allows an incorporation (steam, etc...), a treatment and a residence time adapting best to the product characteristics at dies inlet (temperature, moisture, etc...).

Conditioner

It has a very important part in the pelletizing process.

The best output and quality of pellets will be obtained on the press thanks to a deep and acurate mixing of steam and flour.

Feeding screw

It ensures a sure, regular and controlled food press.

This in order to minimize the operation of the safety measures and controls of the press is:

- Opening of the jam flap on the feeding duct when the intensity increase too much.

- Delay stopping of the feeding

- Breaking possible of the security pins.

Documentation

Standard mixer conditioner type PEP

format PDF

Jul 10, 2018

Brochure about PEP standard conditioners for pellet mills