Circular centrifugal sifters

FEATURES

-

Sealed machine with circular movement for a segregation by centrifugal force

-

Suitable for all types of pellets or dry grains sieving

-

Internal flow adjustment at inlet

-

Scrapping bottom with fines outlet

-

Rotor with scrapping blades assembled at end shaft of a vertical gear-motor

-

Screen mesh according to material specifications

Options :

-

Side outlet with deflector,

-

Large wastes grid and outlet,

-

Atex area 22

PURPOSE

STOLZ circular centrifugal sifters are used to provide a centrifugal segregation for:

- Sieving before grinding.

- Safety sieving after grinding and before mixing.

- Pellets sieving for fines and broken grains extraction.

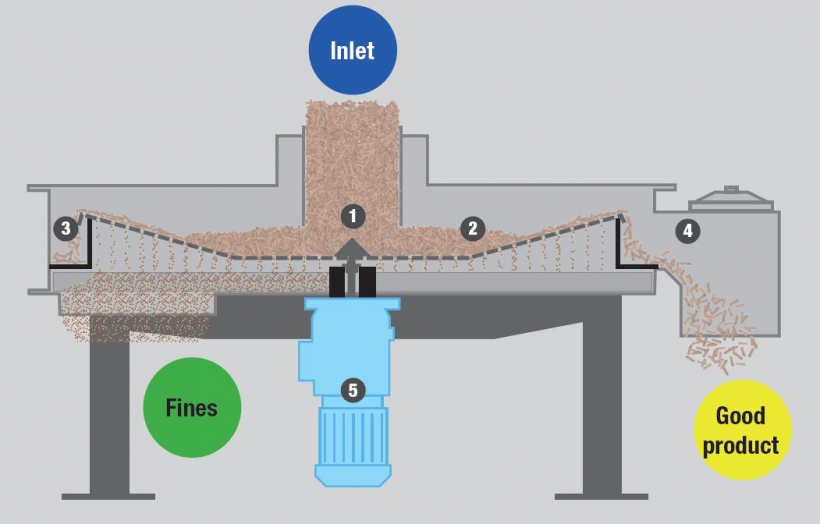

Operating principle

Material to be sieved is introduced at inlet.

A cone (1) dispatches the product over the rotary sieving screen (2).

By a centrifual effect, the product layer slides to the edge while droping out the fines parts : flour, crumbs...

The sieved product then falls into a circular «passage» (3), then into the «good product» outlet (4).

After crossing the screen the fines are collected on the scrapping bottom by scrappers and are rejected to the «fines» outlet.

The rotor is driven by a gear-motor (5) located in the centre with a shaft directly supporting the rotor.

Documentation