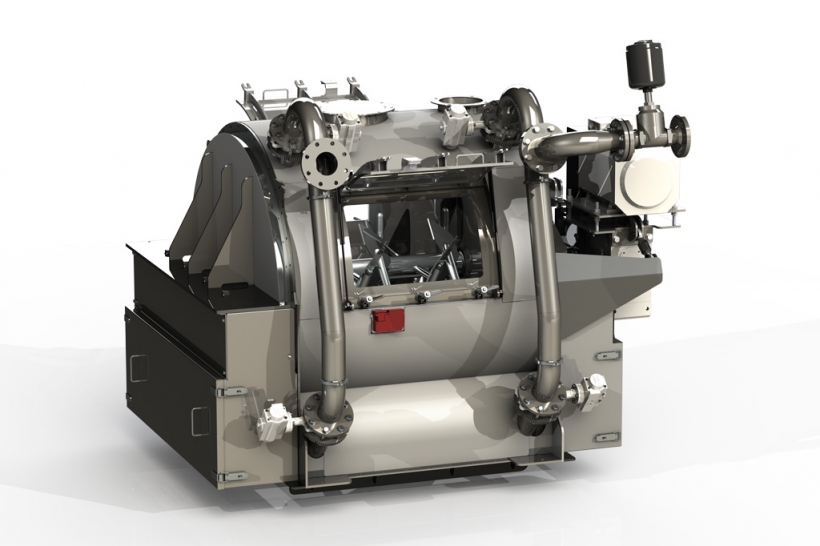

Vacuum coater

APPLICATIONS

Types of liquids additions:

- Fat (+ possible 40%)

- Oils

- Omega 3

- Flavours

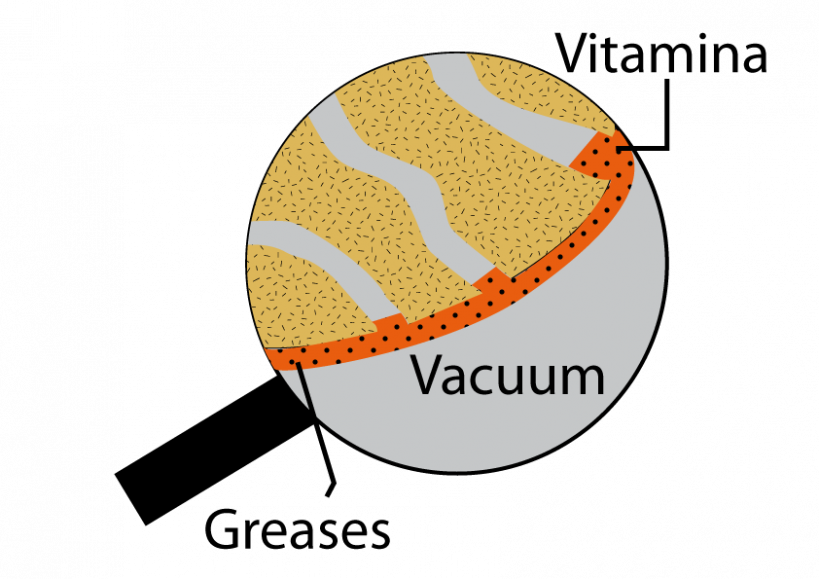

- Vitamins

- Antoxidants

- Pharmaceutical products

- Colourings (pellets)

- Pigments (fish feed)

PURPOSE

With its vacuum coater, Stolz offers state of the art and improved coating.

Mainly intended for petfood, fi shfeed and livestock feed to upgrade their nutritional value by incorporating large amounts of liquid penetrating at heart or bycoating the surface. That solution provides:

- Specific incorporation and distribution

- Upgrade use of additives

- Addition of liquids and powders

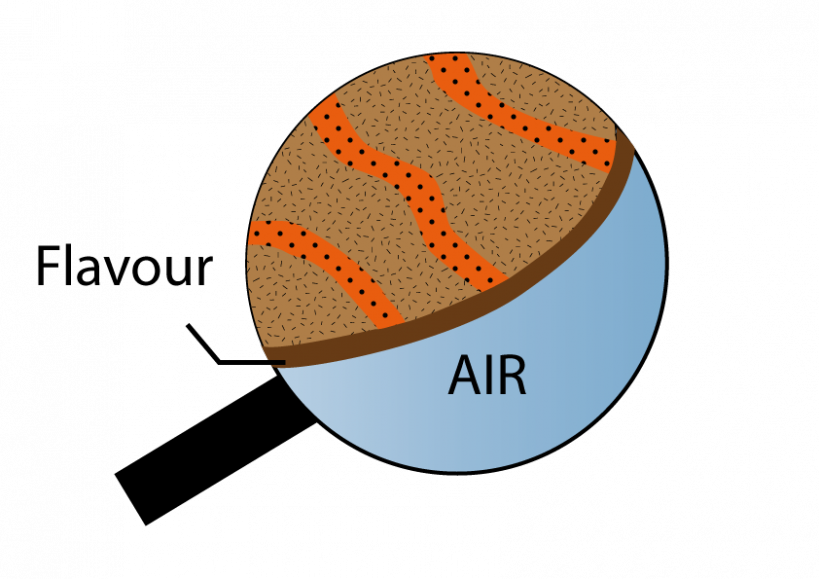

- Multilayer coating technology

- Non-sticky surface state

- Excellent uniformity while reducing the risk of breakage.

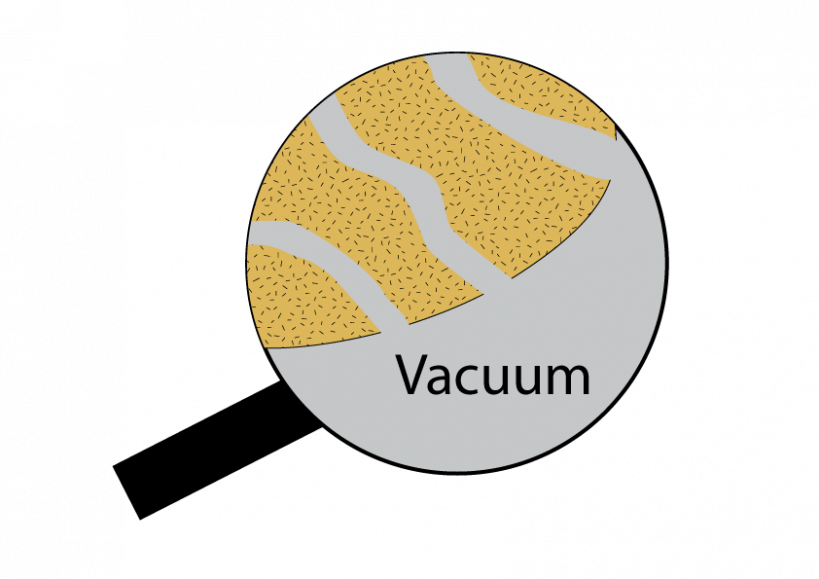

Step 1

The vacuum is caused by pressurisation

Step 2

Incorporation of liquid

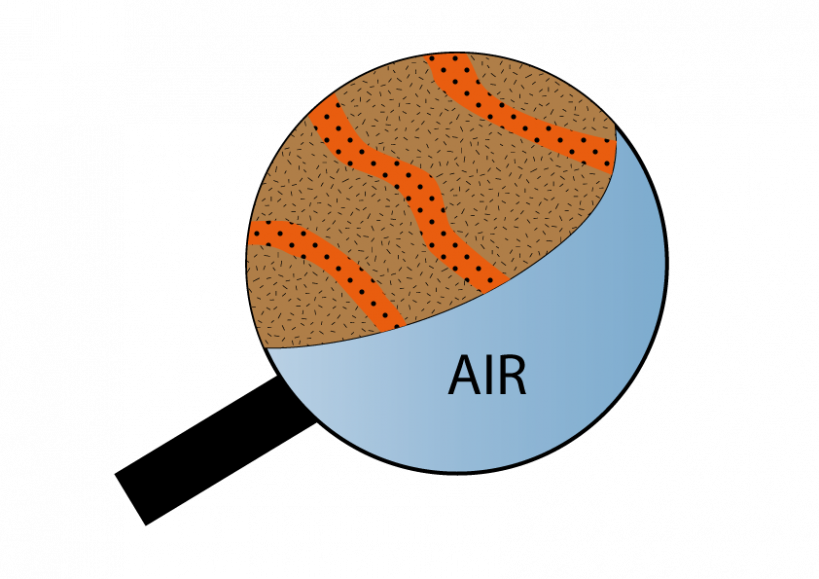

Step 3

New gradual atmospheric pressurisation

Step 4

Final coating with atmospheric pressure and / or powder coating