Twin shafts paddle mixer

CHARACTERISTICS

Laws of gravity challenged

Lack of segregation due to a wide range of bulk densities, of particle sizes or shapes.

Accurate mixing

-

Minor components without premixing : 10 ppm,

-

No overheating,

-

Variation coefficient value less than 3% with powders according to applications.

Wide opening side inspection doors

-

Quick inner inspection,

-

Quick eventual cleaning.

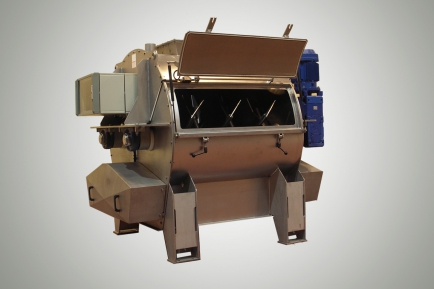

All kinds of steel finishing

Internal finishing

- Stainless steel : all types of grains polishing, electropolishing, seamless welding

- Mild steel : 1 protective coating layer, high wear resistance coating on option.

External finishing :

- Stainless steel : fine glassbeatshot, protecting coating layer on steel plates

- Mild steel : primary coating layer, final coating layers

Video

The mixing

A shorter mixing time

Depending on applications, mixing time is from 10 seconds up to 1 minute to achieve a stabilized mix involving dry material.

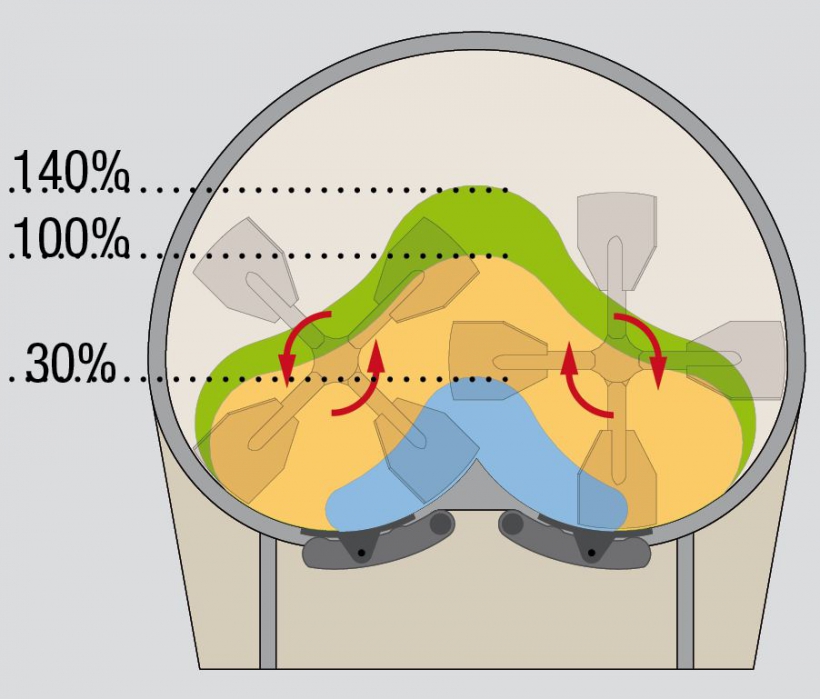

Flexible unit batch size

Loading rate from 30% up to 140% of the nominal capacity according to applications without changing operating parameters.

Shearing and dispersal tulip knives

According to applications, possible addition of active shearing and cutting devices even with a 30% loading rate efficiency.

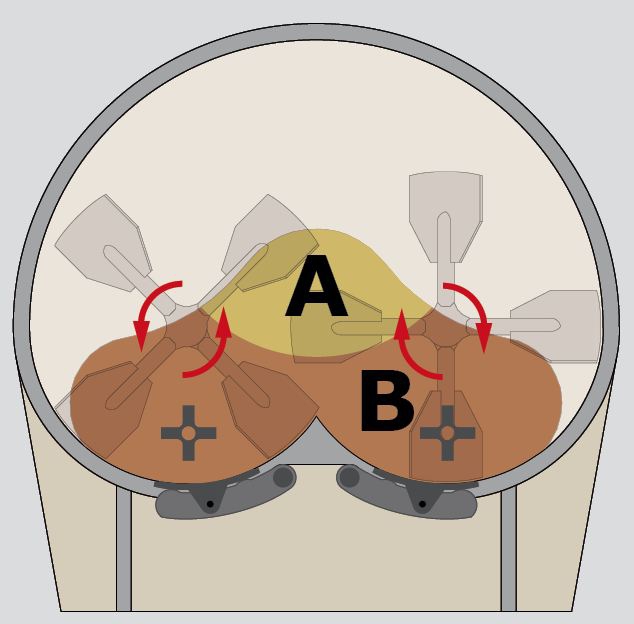

Fluidization and particles movement areas

Direction of rotating shafts :

- The different particles are moved up into the central area of interpenetrating paddles by synchronized rotors.

Area A : Mechanical fluidization area :

- Area for interpenetration of paddles moving downward. Area A is the actual mixing area.

Area B : Circular movement of particles :

- Zone where particles have a circular and planetary movement and move simultaneously with complex movements in area A.

Documentation