Sleeve filters

FEATURES

- High capacity of filtration : up to 210 m² as standard

- Cleaning by counter current compressed air (tank do not require to be proofed again)

- Filtering sleeves adapted to the different kinds of products

- Shapes designed to limit retention of product

- Control of the filtering process of product similar to pads filters

APPLICATIONS

- Centralised cleaning

- Grinding

- Bulk pit cleaning

- Bulk loading cleaning

- Cleaner - Drumscalper

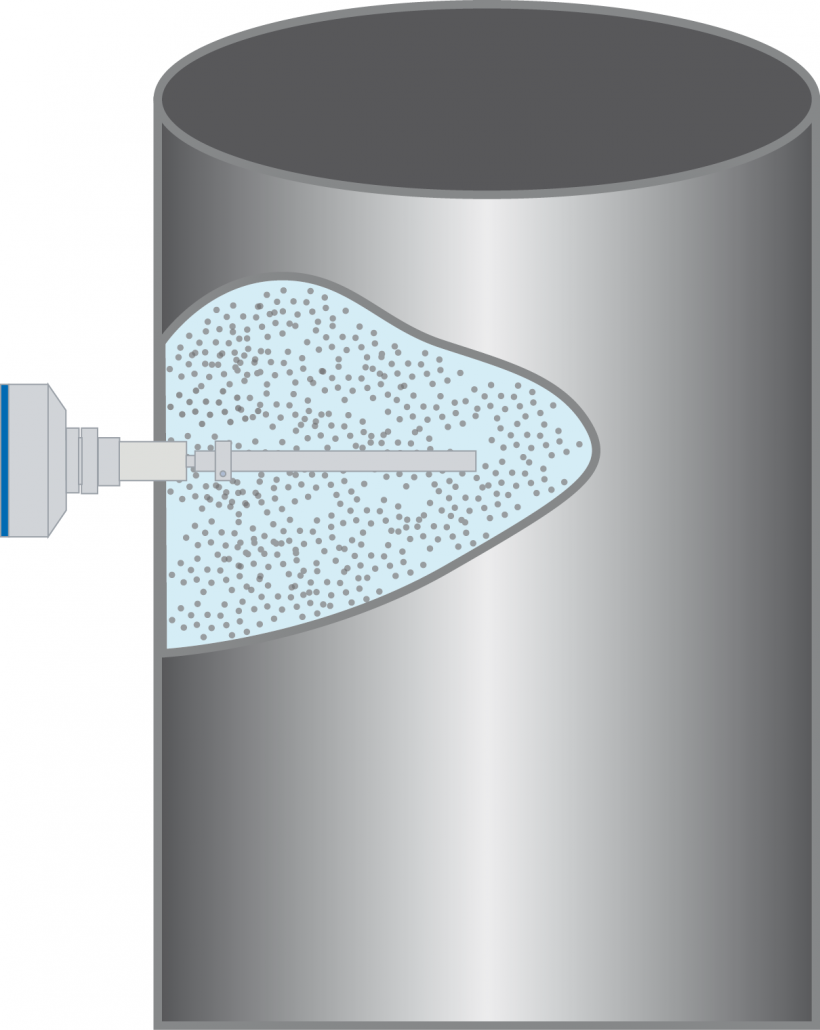

PRINCIPLE

The advantage of the cyclonic effect is a pre-separation of the biggest particles that could damage the sleeves.

Because of its more resistant round shape it can resist to pressure-vacuum:

- Safe installation for Atex zone, protected by explosion vents

- Pneumatic conveying installation

- Cleaning units with vacuum pressure

- Separation of products with high pressure (fine grinding with turbosifter,…)

It can also do a product separation :

- Fines (premix and micronized powders)

- Abrasives (minerals or grains)

- Specific products (starch, chicory, gluten, sunflower cakes, soya, canola)

Dust sensor

The installation of a dust sensor at a cleaning filter outlet can detect an abnormal amount of dust in an air flow.

Some versions can also do a measurement of atmospheric wastes.

In the first case, it can:

- Detect a damaged filtering media

- Detect an explosive atmosphere (Atex)

In the second case, it can also check the compliance to the rules relating to dust wastes.

Documentation

Sleeve filters

format PDF

Jul 10, 2018

Brochure about CFMC cylindrical sleeve filters and CFMP square sleeve filters