Rotary sifters

The need to separate a product batch into 2 different and regular particle sizes, especially in the fi eld of bioethanol, starch, cement, petfood, and fi shfeed lead STOLZ to design a range of high performance rotative sifters, called «turbosifter».

Specifically designed for the separation of fi ne ground products

- Cleaning of screens by air blowing and rotation of screens supports (BCMT version)

- Limited risk of cross-contamination

- Quick change of screens through large sized side doors

- Limited maintenance

- BCMF version with fi xed screens for standard products not requiring any specific cleaning

- Screens from 5 mm to 0.4 mm, or 4 to 40 mesh

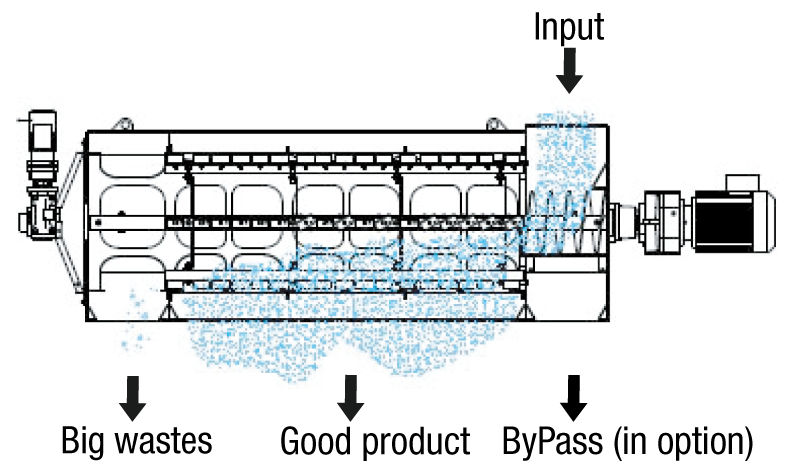

Operating principle

Input spout receive material to treat and a never-ending screw introduces them inside a fixed sift. A rotor with flaps dispatch products on the whole sift square and forced passing over holes or meshes. Rejects by rolling are carried along to exit, whereas small grains passed through sift.

This sifter is fitted with a compressed air blowing system, allowing cleaning of screens at the end of each batch or every five minutes on difficult products.