RME hammermills

FEATURES

-

Two-way rotation

-

Screen exchange when machine stopped

-

Speed 3000 rpm

-

Grinding chamber equipped with grooved armor plates

-

Hammers with high thickness

PURPOSE

That hammermill is derived from the RM range.

It has been adapted to meet reliability criteria required by industries whith important surges requiring a very high mechanical and wearing strength (knackery, paper blocks, cakes, cassava roots, etc...).

That type of hammermill is usually fed by a belt conveyor with adjustable speed.

The powder is conveyed by a hopper and a screw conveyor.

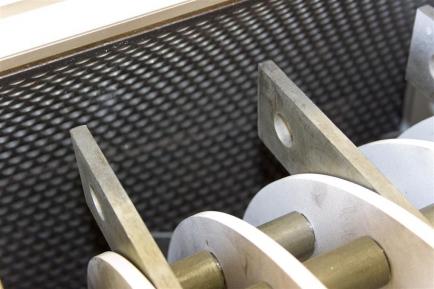

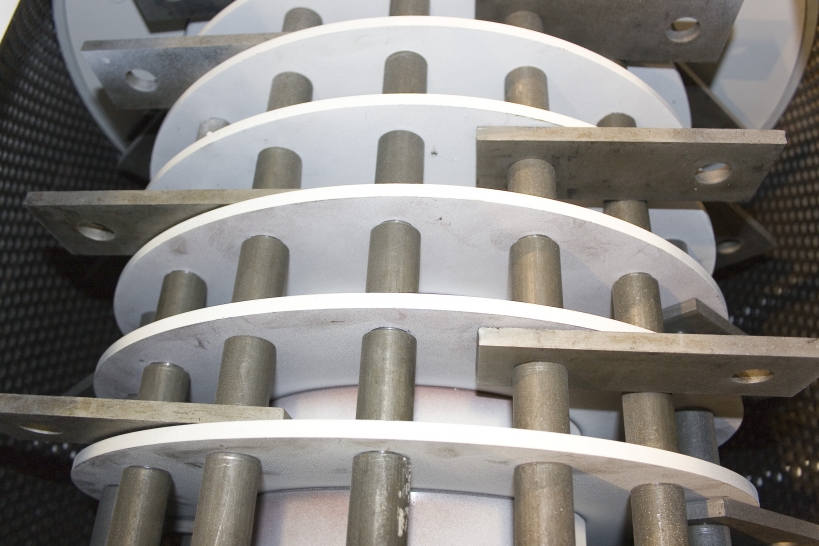

The rotor

It consists of a hard steel shaft provided with braced discs supporting hammers machined in a special alloy and treated steel.

These hammers are bored with two holes to work on the 4 angles, and oscillating on supporting axis made of treated hard steel.

The rotor turns on a plummer block housing roller bearings fitted outside the room.

Their lubrication is ensured by automatic autonomous lubricators.

The drive is ensured by a semi-flexible coupling sleeve.

Documentation

Hammermills type RME

format PDF

Jul 10, 2018

Brochure about hammermills for industries with important surges (knackery, cassava roots, cakes,...)