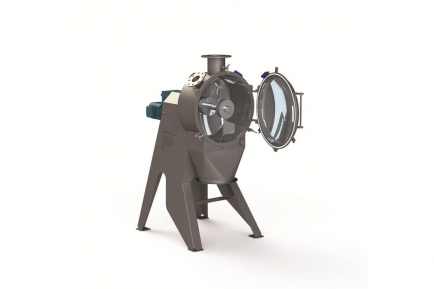

Mixing rotosphere blender

CHARACTERISTICS

-

Stainless steel tank

-

High cleaning ability

-

Mixing quality

-

Complete draining

-

Limited overall dimensions

-

Ability to transfer material via pneumatic transfer by dense phase into the mixer

PURPOSE

With an extremely high flexibility the Mixing Rotosphere will appeal to every user searching for a mixing of small bulk batches and requiring frequent changes of formula.

The product can be injected directly into the mixer by pneumatic transfer.

Its small size design provides an easy integration into an existing production unit.

The Mixing Rotosphere range is available into capacities from 100 to 1 000 litres.

Hygienic design

Mostly dedicated to human food, the Mixing Rotosphere has been designed with a permanent concern of hygiene.

The treatment of the tank by polishing ensures a minimal adhesion (RA 0.8), limiting material residues deposits, while reducing the required energy for mixing.

With its full opening tank and single bearing shaft the Mixing Rotosphere can be easily cleaned: 100% of the components in contact with the product are reachable.

The blasted stainless steel external part of the device is also tight to hose.

Designed for small units

STOLZ is well known for its high capacity mixers (up to 15 000 litres). With the Mixing Rotosphere range we wanted to bring to the laboratories, test units, small production units or cooperatives our technological know-how.

The Mixing Rotosphere ensures the mixing of small size batches and provides a fast change from one batch to the other without contamination.

The mechanical part is designed to limit maintenance, save energy and offer reliable STOLZ equipment.

Video

Documentation