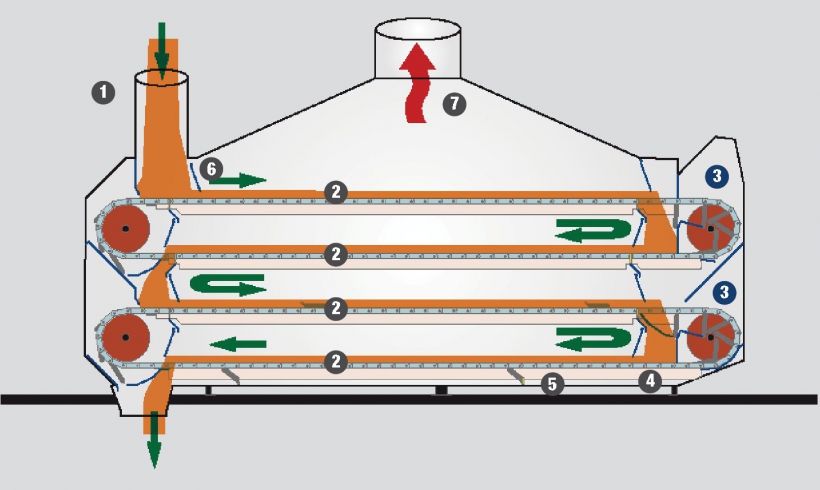

Horizontal coolers

PURPOSE

The cooler is designed to lower the temperature and moisture of the product to values close to ambient temperature.

That operation improves the durability and preservation of the pellets.

PRINCIPLE

The warm products produced by the pellet mill are placed into the horizontal cooler via a swivelling valve distributing them uniformly all over the machine width.

The pellets to be cooled down are thus laid down onto a metal belt made of bored components conveying them and preventing them from moving, thus not breaking them, for a preset time and speed to reach a temperature between 5 to 10°C maximum above the ambient temperature.

Operating principle

-

A swivelling valve ensure a uniform and regular feeding all over the belt width.

-

Conveying belt designed with bored components assembled on traction chains. The sliding paths of the chains are isolated from the product avoiding any damage risks of the pellets.

-

Automatic device for pellets cooling level change ensuring the layer height uniformity. A permanent cleaning device is installed at the end of each level.

-

Guide flaps forcing the air to pass through the pellets layer.

-

Complete cleaning of the cooler with a silent bottom scraping brushes device.

-

Flap for layer height control.

-

Warm air suction.

Documentation