Bucket elevators

FEATURES

-

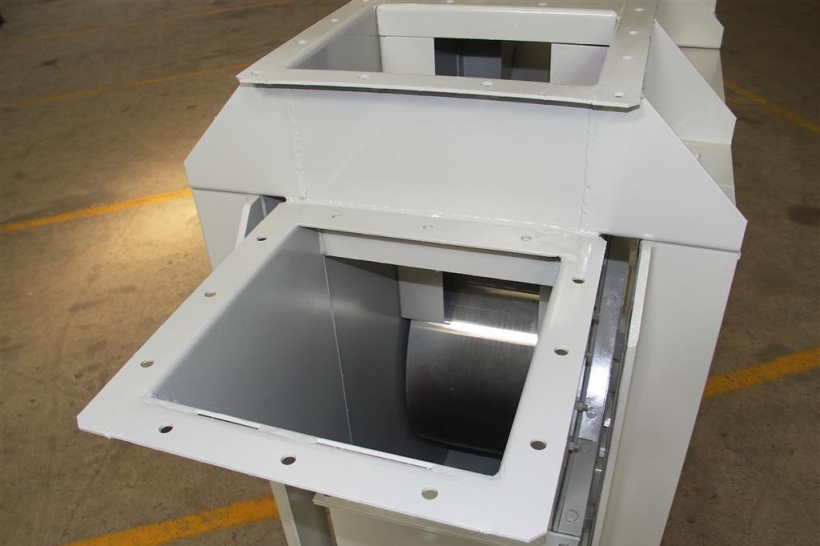

Protection of the head ejection area a gainst abrasion

-

Adjustable and flexible outlet skirt

-

Dismountable sheath

-

Any type of buckets and belts or chain

-

Possible slow speed for fragile products

PURPOSE

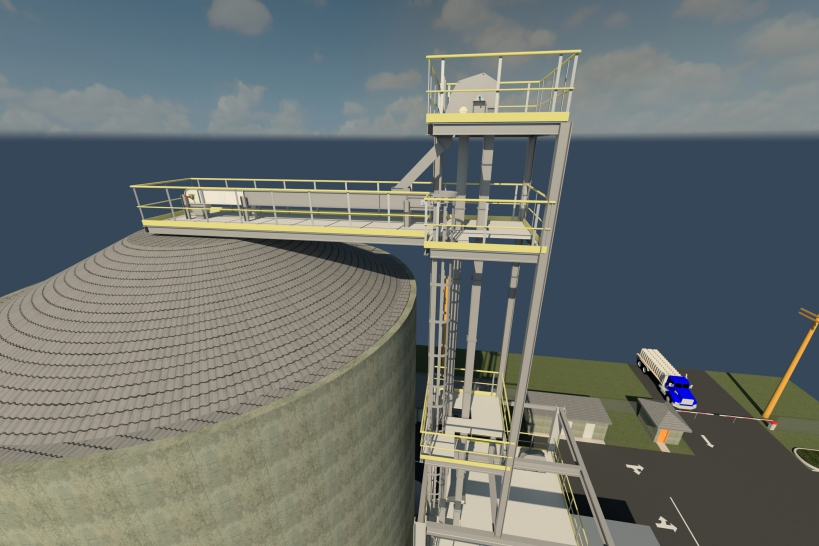

A bucket elevator is designed for the handling and extracting of granular and powdery products over a vertical linear trajectory.

Our wide range of standard elevators allows capacities up to 1600 m³/h.

For applications not included in this range, our Design Offices are qualified to develop specific elevators meeting any requirements.

Options

-

Optimized discharging foot

-

Suction intake or built-in dedusting filters

-

Gradual progress for maintenance

-

Feet above ground for easy maintenance

-

Refeeding inlet

Safety devices

-

ATEX compliance 94/9/CE on demand

-

Belt misalignment control

-

Rotation control

-

Clogging detection

-

Product flow detection

Solutions for limited explosion risks

STOLZ solutions to limit explosion risks:

- Use of antistatic (ISO284) and self-extinguishing (ISO340) belts

- Fitting of explosion vents (to be specified according to each elevator: installation, capacity, KST product…)

- Dedusting at feeding inlets and outlets

- Misalignment belt control

- Rotation control

- Bearing temperature control (option)

- Inert gas injection

Documentation