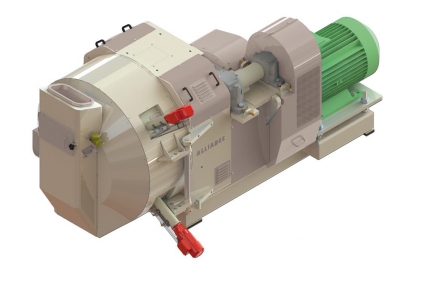

Alliance pellet mill

FEATURES

-

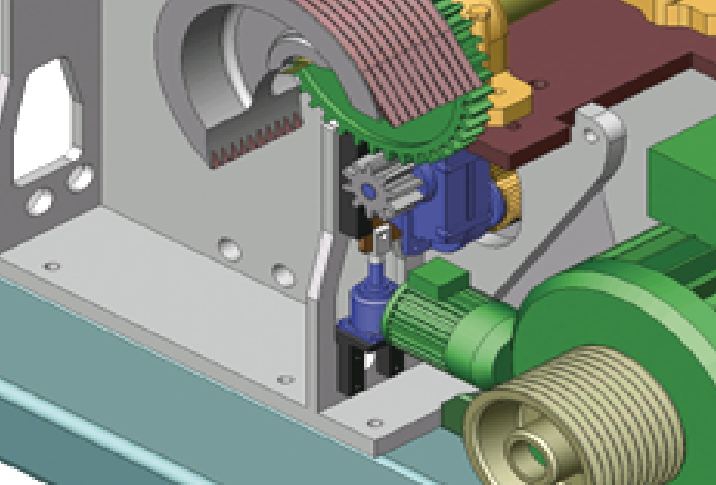

Transmission using a double set of belts designed for a modulation of the die speed according to the type of product (3,8 to 6,7 m/s)

-

Restricted vibration level : guarantees a long life of the pellet mill

-

Height compact construction making the replacement of an existing pellet mill easier

-

Absorption of shocks in case of a sudden overload

-

Low noise level

-

Limited risk of contamination

-

Easy and limited cleaning

-

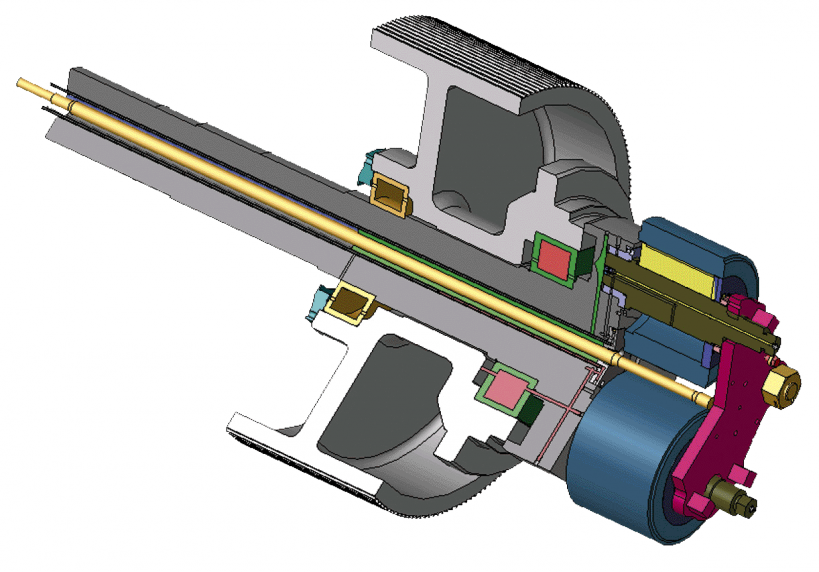

Pellet mill central system largely sized guaranteeing long-lasting rollers and die while improving operating quality.

Options

The Alliance pellet mill can include several options to optimize and secure operation while limiting the operating and maintenance costs.

All options can be added up and set up in the future:

- Rollers temperature control

- Ultra slow two-way die speed

- Forced feeding by screw

- Limited contamination by draining the used grease

- Automatic distance between rollers and die

- Motorized pellet knives

- Heated door

- Regulation of meals and steam feeding

PURPOSE

Pellet mill range designed for the compression of powdery products for animal nutrition meeting health, safety and normative requirements, or for the compression of any product.

Ultra slow die speed

- Slow disengageable motorized rotation.

- Two-way die rotation.

- Ultra low speed (1 rpm) and strong available torque.

Advantages:

Helps to release the product.

Easy repositioning of the safety pin.

Adjustment control of clearance between die and rollers.

Automatic greasing

Design allowing the recovery of used grease.

Automatic distribution on:

- The roller bearings

- The main shaft bearings with discharge of the used grease at the rear of the pellet mill.

Advantages:

Limits the pellet contamination with grease.

Lower costs : food grade grease use is not required.